Blast Room is widely used in shipbuilding industry, military, and engineering machinery, petrochemical machinery, hydraulic machinery and bridge structures, locomotives and etc. and is suitable for large metal structure before painting surface blast cleaned and shot peening treatment .sandblasting processing can thoroughly clean the surface of work piece of welding slag, rust, descaling, grease, improve surface coating adhesion, achieve long-term anti-corrosion purpose. In addition, using shot peening treatment, which can eliminate the work piece surface stress and improve the intensity.

1.BLASTING CHAMBER/ BLASTING ROOM:

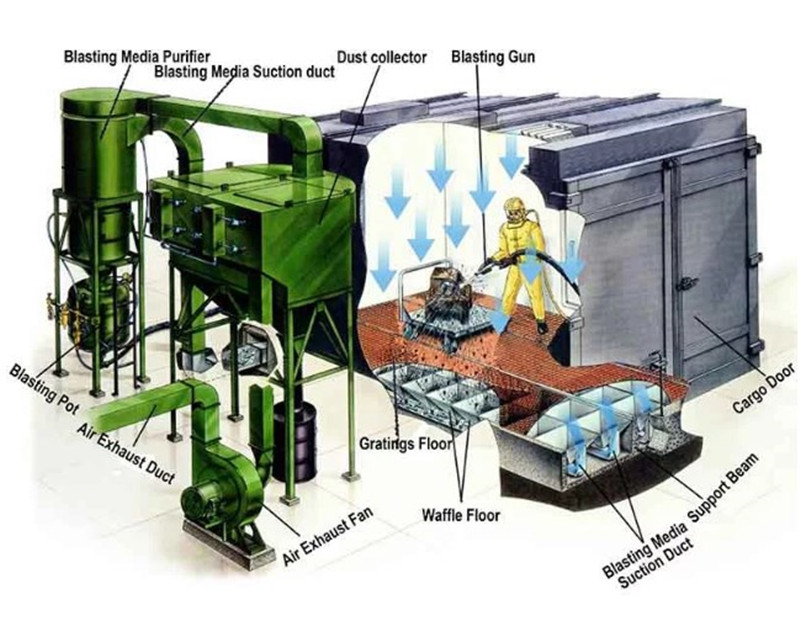

It consists of the entire physical structure and closing of the whole abrasive blast operations. and it’s typically made of structural steel, cladding, or sandwich panel steel. The blast room usually uses rubber or polyurethane abrasion-resistant liner to protect the steel walls and ceiling and assist with sound dampening.The blast booth includes other critical elements, such as doors, lighting, ventilation, work handling, et cetera.To drive the ventilation of a blast chamber, we require a dust collector. It consists of the entire physical structure and closing of the whole abrasive blast operations

2.Abrasive reclaim system;

Which transports spend abrasive media after blasting to the abrasive of recycling and cleaning unit.

The good reusable abrasive media can be delivered to the blast equipment.

The spray gun can be one or two, and customers are free to choose.

5.Dust collector

Using a filter cartridge dust collector, the dust removal effect is 99